截至2008年10月,全国设市城市、县及部分建制镇共建成污水处理厂1459座,日处理能力8553万吨(36个大城市共建成288座,日处理能力为3497万吨),分别比“十五”末期增加60.5%和42.6%,全国设市城市污水处理率已由2005年的52%增加到2007年的63%;在建城镇污水处理项目1033个,设计日处理能力约3595万吨。2008年1至10月,全国已投入运行的城镇污水处理厂累计处理污水达190亿吨,运行负荷率达到76%,同比分别增长了21%和约3个百分点。

虽然由于国家和各级对环境保护重视程度的不断提高,中国污水处理行业正在快速增长,污水处理总量逐年增加,城镇污水处理率不断提高。但中国污水处理行业仍处于发展的初级阶段。

潍坊某橡塑有限公司位于的中国蔬菜之乡——山东省寿光市,该企业产生污水主要包括工业废水和生活污水。工业废水主要来源于工艺生产中间隙排放的高浓度废液(脱脂、磷化、电泳废液等)和连续排放的脱脂溢流废水、水洗废水、磷化溢流废水及电泳废水、喷漆废水等。

As of October 2008, the national city, county, and part of the key town built sewage treatment plants 1459, daily processing capacity of 85.53 million tons (36 cities were built in 288, daily processing capacity of 34.97 million tons), more than the "15" at the end of 60.5% and 42.6% respectively, the national city urban wastewater treatment rate has increased from 52% in 2005 to 63% in 2007. There are 1,033 sewage treatment projects under construction, with a design day processing capacity of about 35.95 million tons. From January to October 2008, the cumulative treatment of sewage in urban sewage treatment plants in the country reached 19 billion tons, and the operation load rate reached 76 percent, up by 21% and about 3 percentage points respectively.

Though because of state and government at all levels of the importance of environmental protection, sewage treatment industry in China is growing rapidly, sewage volume increased year by year, urban wastewater treatment rate to improve. But China's sewage treatment industry is still in its infancy.

Weifang one rubber and plastic co., LTD. Is located in shouguang city, shandong province, the hometown of famous Chinese vegetables, which produces sewage mainly including industrial wastewater and domestic sewage. Industrial wastewater mainly comes from the high concentration waste liquid discharge process in the production of clearance (degreasing, phosphating, electrophoresis liquid waste, etc.) and continuous emissions skim the overflow of wastewater, water washing, phosphating wastewater overflow wastewater and electrophoretic wastewater, spray paint waste water, etc.

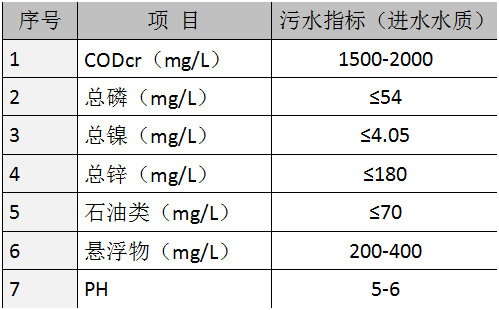

处理工业污水水质

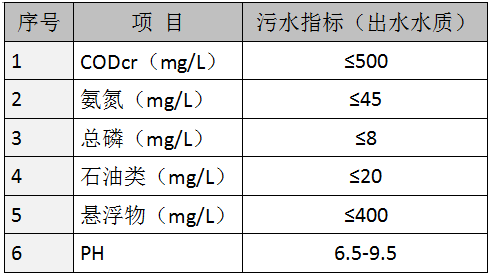

排放标准

工业污水处理方案:

来自生产车间的生产废水0.5m3/h,通过厂区内自流管道自流至隔油调节池,将污水中部分悬浮石油去除,在调节池内进行PH的调节。

隔油调节池的废水经过P1泵提升至斜管沉淀器,在沉淀器内通过加药絮凝作用将废水中的金属离子及悬浮物去除。经斜管沉淀器作用后,废水自流进溶气气浮机,通过气浮机的微小溶气气泡将污水中大部分悬浮油以及乳化油去除,气浮过程中为更好的去处浮油以及悬浮物需通过加药装置投加PAC、PAM,通过絮凝剂的絮凝作用,将污水中的小颗粒悬浮物絮凝成大颗粒悬浮物,更高速有效的去处水中的浮油以及悬浮物,为后续的生化部分提供条件。污水经气浮机除油后进入一体化处理装置。

一体化处理装置;一体化废水处理装置分水解酸化段、接触氧化段、和二沉池;实现废水水处理的生化全过程,二沉池设置污泥回流泵P2,实现A/O工艺的硝化液回流,初期的污泥量及生化处理的效果。

沉淀池出水自流进入排水官网,至此达标排放。

济宁天通设备有限公司是一家从事水处理设备生产、销售集一体化的企业,经过不断的努力在国内外获得了供不应求的大好市场,赢得了客户的一致好评。多年的发展历程,公司始终坚持创新、品质、服务、敬业、感恩的理念。采纳新创意,严格质量,的服务跟踪,坚持做出产品。

我公司主要产品:水处理设备,污水处理设备、废水处理设备、工业污水设备、农业废水设备、雨水净水设备、医院污水设备、钢厂废水设备、屠宰场废水设备、食品厂废水处理设备等多种设备,可根据要求定制水处理设备。

The production wastewater from the production workshop is 0.5m3/ h, and it flows through the self-flow pipe in the factory to the oil regulating pool to remove some of the oil from the wastewater and adjust the PH in the regulating pool.

The waste water from the oil regulating pool was raised to the inclined tube precipitator by the P1 pump, and the metal ions and suspension were removed from the waste water by adding drug flocculation in the precipitator. Gravity by the inclined pipe and setting device, the waste water into the dissolved air flotation machine, through tiny dissolved air bubbles of air floatation machine remove most of the floating oil and emulsified oil in sewage, air flotation process to better use oil and suspended solids by dosing PAC and PAM dosing device, through the flocculation flocculant, the sewage of small particles suspended solids flocculated large particles suspended matter condensed, more high speed and effective place to the oil and suspended solids in the water, biochemical section provides conditions for the follow-up. After oil removal, the sewage gas float can enter the integrated treatment device.

Integrated processing unit; The integrated wastewater treatment plant is divided into the hydrolytic acid segment, the contact oxidation section, and the sink pool; To realize the biochemical process of wastewater treatment, the sludge backflow pump P2 was set up in the sink pool to realize the flow of the nitrification solution of A/O process, ensuring the initial sludge volume and the effect of biochemical treatment.

The water flow of the sedimentation tank enters the drainage website.

Jining day general equipment co., LTD. Is a company engaged in water treatment equipment production, sales integration enterprise, after continuous efforts won the demand of the market both at home and abroad, won the customer consistent high praise. Over the years, the company has always adhered to the concept of innovation, quality, service, dedication and gratitude. Adopt new ideas, strict quality, all-round service tracking, insist on making high-quality products.

My company main products: water treatment equipment, sewage treatment equipment, wastewater treatment, industrial wastewater, agricultural wastewater, rain water purification equipment, hospital sewage equipment, steel plant waste water equipment, slaughterhouse wastewater treatment equipment, food factory waste water treatment equipment and other equipment, can professional custom according to the water treatment equipment.